AeroDef Manufacturing 2018 - Booth 1022 SPRING Technologies to demonstrate how automation and optimization software can maximize shop floor capabilities

AeroDef Manufacturing 2018 – Booth 1022

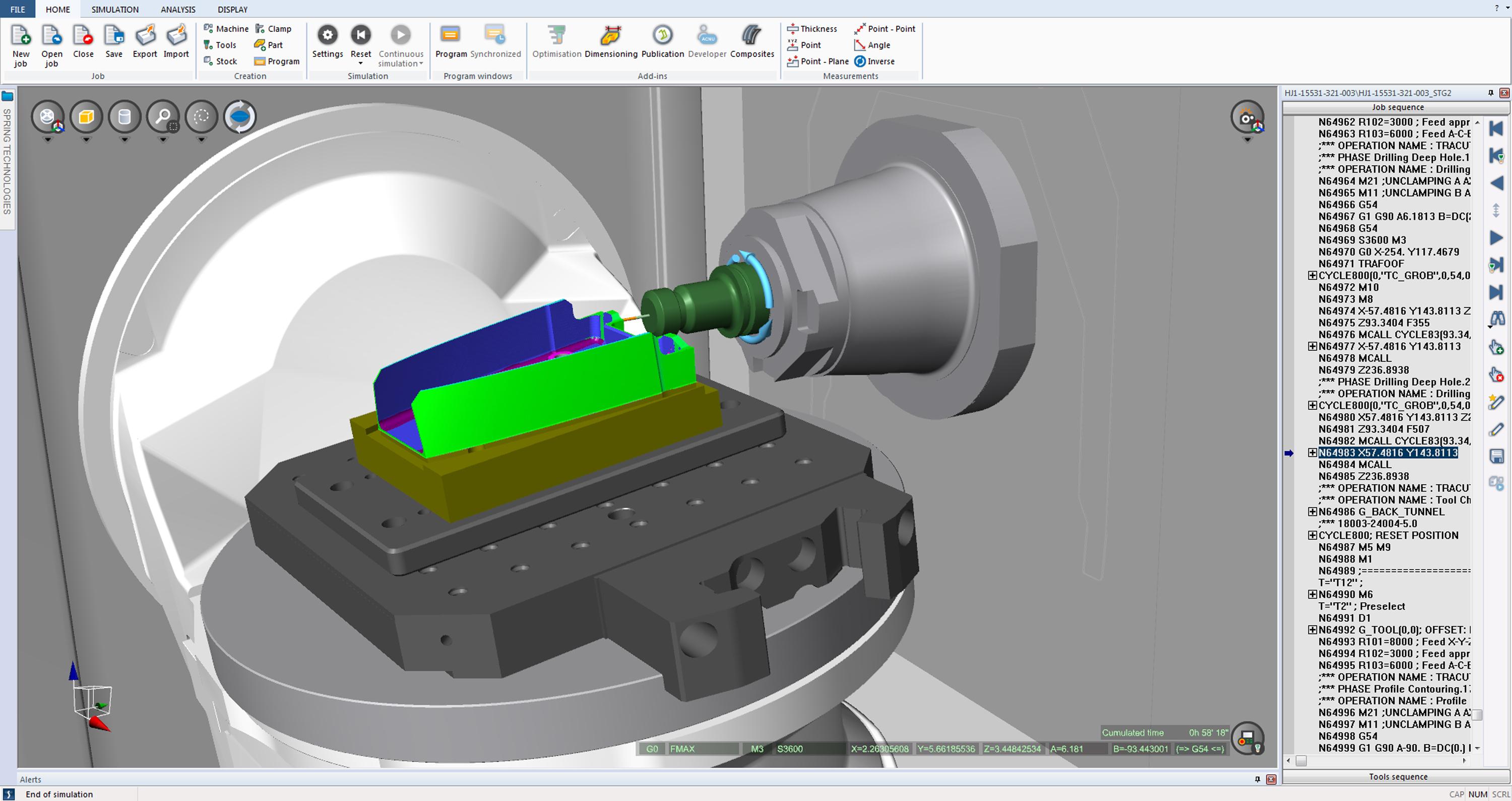

Boston, MA January 2018 – SPRING Technologies, developer of software for CNC machining simulation and optimizing CAM programs, will demonstrate its flagship NCSIMUL package at AeroDef 2018, Booth 1022. The conference and exhibits event will span March 26 - 29 in Long Beach, California. The latest version of NCSIMUL sets a new benchmark for comprehensive control of the machining process, providing ease of use, flexibility and automation for manufacturers to move towards Industry 4.0. The two main modules, NCSIMUL Machine and NCSIMUL 4CAM will be highlighted at the event, along with NCSIMUL OPTITOOL.

“Without compromising the integrity of the shop floor, our software has the ability to streamline capabilities that work to complete and optimize any project overnight using automated processes,” said Silvère Proisy, North American Operations Director for SPRING Technologies. “Of particular interest to aerospace OEMs and its suppliers, this approach provides room for more innovation during the day and without risking thousands of dollars in equipment and machinery. Flexibility drives productivity with automation tailored to any shop floor.”

New features of NCSIMUL and the NCSIMUL 4CAM

Among the newer features of NCSIMUL and the NCSIMUL 4CAM module are: New probing strategies; support for turning after milling, for one-click NC machine turnaround; cutting tool management with 3D definitions; one-click project update; project export/import; automatic performance analysis; automatic graphic detection of machining risk zones and less than optimal cutting conditions, and more. The improvements are contained in the NCSIMUL OPTITOOL module of NCSIMUL Machine include algorithms that transform working feed rates into rapid feed rates or specified maximum feed rates for approach and retract motions in both circular and linear toolpaths. The software's Air Cutting Optimization mode can enable users to reduce machining times by 4 – 25 percent by minimizing air-cutting motions and optimizing entry and exit feed rates. This results in immediate and automatic savings on every part produced, even on existing programs.

Simple, one-click implementation requires no alteration to the toolpath or existing CAM system. The software is effective in Fanuc, Heidenhain, Siemens and any other standard CNC control languages. NCSIMUL OPTITOOL also enables users to test different optimization strategies and provides graphic analysis comparing initial and optimized feed rates. Further, this optimization can be applied (repeated) on every machined part currently in process, multiplying the gains.