CTRM Malaysia adopts NCSIMUL Machine from SPRING Technologies for its new implemented 5-axis gantry-type machines

« With NCSIMUL, we reduce the time for dry runs (99%) and risk of collisions/problems during the machining process. »

Composites Technology Research Malaysia Sdn Bhd, well known as CTRM Malaysia, is a leading global player in the composites and aerospace industry. Entrusted with a strategic role to develop high technology based industry, namely the aerospace and composites industries. The government identified these two industries as the most crucial constituents to future industrial growth for Malaysia.

CTRM: YOUR PARTNER IN COMPETITIVE SOLUTIONS In line with its Corporate Vision "To be the CENTRE OF EXCELLENCE for composites and aerospace" and its Mission "To be the PARTNER OF CHOICE in composites and aerospace through the development of people, capabilities and products", CTRM started its business operations with the assembly and manufacturing of a two-seater composites light aircraft, the Eagle 150B. Today, CTRM is part of the global supply chain of composite aero structures for major commercial and military aircraft manufacturers in the world.

Apart from manufacturing composite aero structures, CTRM is also providing engineering design services, composite parts assemblies, composites R&D, automotive composite structures, and defense-related equipment, including the Tactical Unmanned Aerial Vehicle.

CHALLENGES

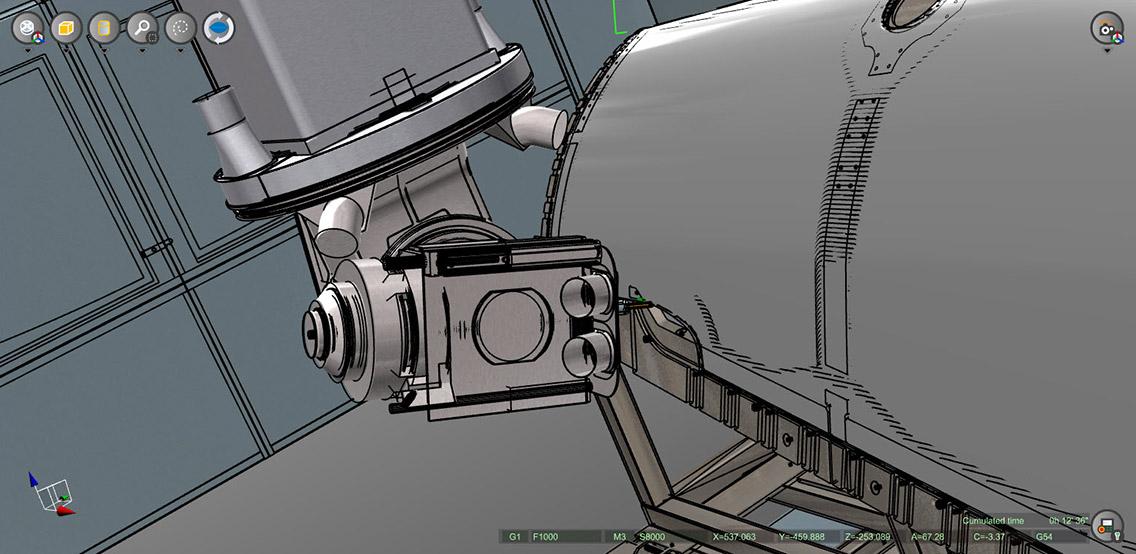

CTRM started new composite parts production on their newly implemented 5-axis gantry-type machines. Large machines, parts and complex processes often lead to manufacturing issues such as inaccurate hole positions, over trim at the end of edges, collisions because of unsuitable cutting tools and programs or insufficient tool-length. These issues can add to very high costs for online debugging, many setups and scrap parts. The NC programs and cycles using the machines' physical properties such as linear motors, automatic tool changer, automatic dust extractor attachment changer, multiple axes working simultaneously, automatic laser tool offset measurement, workpiece probing, special design drilling tools, and more needed to be fully verified and simulated before sending the final program to the actual machine.

CTRM looked for a comprehensive machining simulation software for developing, optimizing and running machining programs meant for NC machine tools and ultimately chose NCSIMUL Machine from SPRING Technologies for its high-speed G-Code Simulation, user-friendly interface and ability to decode and simulate all programs, sub-programs and complex macros out of any CTRM NC Machines.

KEY BENEFITS

Benefits of using the Virtual Machine within the NCSIMUL Machine environment have been significant from the beginning. The process of debugging and verifying was transferred from the real machine to the virtual machine on the programmers' computers. CTRM identified the following advantages:

- Offline development program for new projects, complex shapes and improvement campaigns.

- Increase productivity through performance. With NCSIMUL, they reduce the time for dry runs (99%) and risk of collisions and other problems during the machining process. All program verifications for their existing machines and all future machines are done offline, leaving the machine for production only.

- Detect the errors and mistakes of the NC program that caused collisions between spindle head, tool holder and fixture.

- Optimum CNC machine running.

- NCSIMUL Machine has great technical service and support in Malaysia from local suppliers based in Kuala Lumpur and Penang