Desktop Engineering & SPRING Technologies announce NCSIMUL Machine 9 in UK

DTE and SPRING Technologies announce the UK Launch of NCSIMUL Machine 9

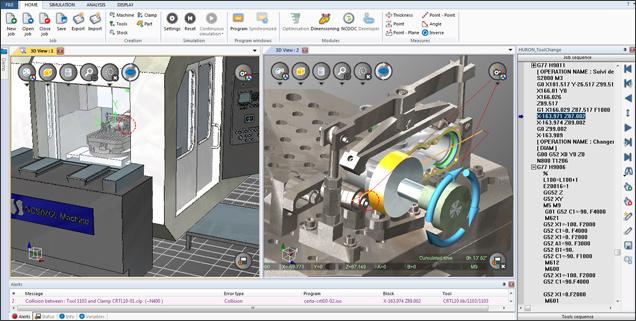

Oxford, UK, XX May, 2013 – Desktop Engineering, a leading engineering software solutions provider and strategic business partner of SPRING Technologies, today announced the commercial availability of NCSIMUL Machine 9. SPRING Technologies latest version of NCSIMUL Machine ushers in the "NCEXPERIENCE", a milestone in machine simulation which will enable manufactures to achieve real-time synchronisation of their physical and virtual machining cycles. The new solution offers customers a more realistic, intuitive, integrated and hands-on NC simulation experience, with extended functionality dedicated to multitask and multi-axis machining centres.

Geoff Haines, managing director at DTE, said: "Within the manufacturing sector, there is a requirement for a more robust digital production process that is interactive and integrated. SPRING's latest software release, fulfills this need and makes 'smart machining' a business reality."

Overview benefits of NCSIMUL Machine 9 are:

- Simplified ergonomics, for faster and more widely available NC machining

- Enhanced user experience, quicker adoption and more robust interaction with the NC machine

- Increased performance, equates to more productivity and faster ROI

- New functionality, enabling generative, dynamic NC programming to become even more interactive

- Tighter integration, for a leaner digital process (integrated tool libraries and cutting conditions and new CAM interfaces e.g. CATIA V6)

NCSIMUL Machine 9 offers a unique experience, based on state-of-the-art technological standards, in terms of both ergonomics and ultra-mobility. Realistic simulation, integrating all machine, tool and material parameters, will quickly become routine to manufactures. Corporate-wide deployment makes it accessible at all times, from a CAM workstation to an NC machine operator on the shop floor. In addition, it has been developed to interconnect with other software packages, most notably Material Resource Planning (MRP) and Manufacturing Execution Systems (MES).

Olivier Bellaton, general manager at SPRING Technologies, said: "With NCSIMUL Machine 9 companies will be getting end-to-end control of their machining process. Through our process and application-oriented models, we automate the creation and distribution of technical content which can now be accessed by an operator right next to the machine, with guaranteed real-time updates of all business critical information."

NCSIMUL Machine is the most advanced CNC machine simulation solution for simulating, verifying, optimising and reviewing machining programs based on the real characteristics of your NC machine (machining, drilling, riveting). 3D graphics help to avoid machining crashes while powerful algorithms and embedded process-based know-how enable cutting conditions optimization, and standardisation of shop-floor documentation. NCSIMUL Machine verifies NC programs in three steps: investigates and corrects coding errors, simulates to locate collisions and correct motion errors, and validates the NC program.

About Desktop Engineering

Founded in 1986, Desktop Engineering (DTE) has developed an extensive customer base in the automotive, aerospace, architecture and general mechanical engineering markets. As a business partner of Dassault Systѐmes, DTE provides CATIA-based Product Life Cycle Management (PLM) solutions. As a full service provider, DTE trains and supports its customers in the use and application of the solutions, together with methodology development to improve design productivity and efficiency. In addition to specialized software to improve CNC manufacturing processes, DTE develops post-processors, programs solutions for robotic welding, cutting and jointing processes, and implements manufacturing simulation solutions. For more information visit: www.dte.co.uk