EMO 2013 : NCSIMUL SOLUTIONS, Panasonic's Toughpad, and FANUC set new machining standards

Check out the comprehensive, integrated, connected and mobile process that delivers unrivalled productivity and quality gains, Hall 25 - Booth G27

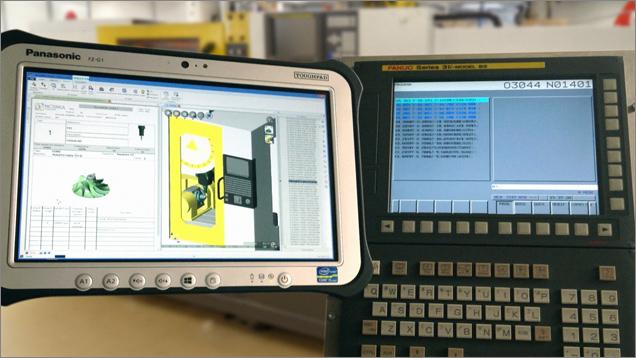

SPRING Technologies, vendor of software solutions that enhance the productivity of CNC machines, will be at EMO 2013, the world's n°1 trade show dedicated to the machining of metals and machine-tools, in Hanover from September 16-21, 2013. SPRING Technologies will be demonstrating a complete, real machining cycle on a FANUC Robodrill 5-axis machine, connected to flagship solutions for tool management, technical documentation and NC simulation review, DNC and machine status monitoring on Panasonic's fully-rugged touch tablet.

SPRING, Panasonic and FANUC: state-of-the-art technologies serving the workshop and delivering unrivalled productivity and quality gains

SPRING Technologies is driving forward its NCEXPERIENCE© vision with a live demonstration of its flagship solutions for machining simulation (NCSIMUL Machine 9 and NCSIMUL Player 9), tool management (NCSIMUL TOOL), and DNC/machine status monitoring (NCSIMUL DNC), implemented on Panasonic's fully-rugged professional tablet, connected to FANUC Robodrill machine-tools.

Here is a preview of the leading-edge technologies showcased on booth G27, Hall 25 at the EMO tradeshow:

- Panasonic's unrestricted mobility: the Toughpad FZ-G1 embodies over ten years' experience in the development of rugged computers for professionals on the move. With 8-hour stand-alone operation (optionally extended to 16 hours with a marathon battery), a magnesium chassis and elastomer edges, the fully rugged tablet is optimally protected for a full day's work in the field, with resistance to bad weather, water, and dust. Thanks to Panasonic-SPRING Technologies "ISV" partnership, the Toughpad is now fully integrated to NCSIMUL SOLUTIONS offering.

- High-performance FANUC machining: FANUC's aD21MiA5 Robodrill is a complete CNC machining center offering unrivalled quality and precision, and very high hourly output. Its optimal acceleration and deceleration control enable efficient machining and shorter cycles. It delivers more than 40% energy savings with reduced weight and mass, pneumatic power supply, implements smart control technology and has an excess energy recovery system.

- SPRING's integrated machining process: NCSIMUL SOLUTIONS range is now accessible and mobile to anyone involved in the production process, throughout the workshop. It is fully synchronized with production devices (machine-tools and NC, measurement benches, etc.). For example, access to documentation in the machining environment and real machine operation display are automated, eliminating the need to download documentation as a separate task.

The SPRING Technologies team and technology partners look forward to meeting you as from September 16 at EMO, booth G27, Hall 25.