Flexible and efficient CNC processes in the aerospace industry

SPRING Technologies presents award-winning software at the "Machining Innovations Conference for Aerospace Industry"(MIC) in Hanover

SPRING Technologies is participating as an exhibitor in the 16th international "Machining Innovations Conference for Aerospace Industry 2016" (MIC2016). The conference will be held at the Hanover Centre for Production Technology (PZH) of the Leibniz University on November 23rd/24th, offering experts from industry and research within the aerospace industry a common international platform to discuss trends, challenges and innovations in production technology .

SPRING Technologies can look back on a long-time experience in NC simulation especially in the aerospace market and is also collaborating with leading research institutes in this area. Its solutions for NC simulation are in use at AIRBUS already since the 1990's and at many other aerospace suppliers worldwide and in the German-speaking region.

Reduced machining and programming times as a competitive advantage

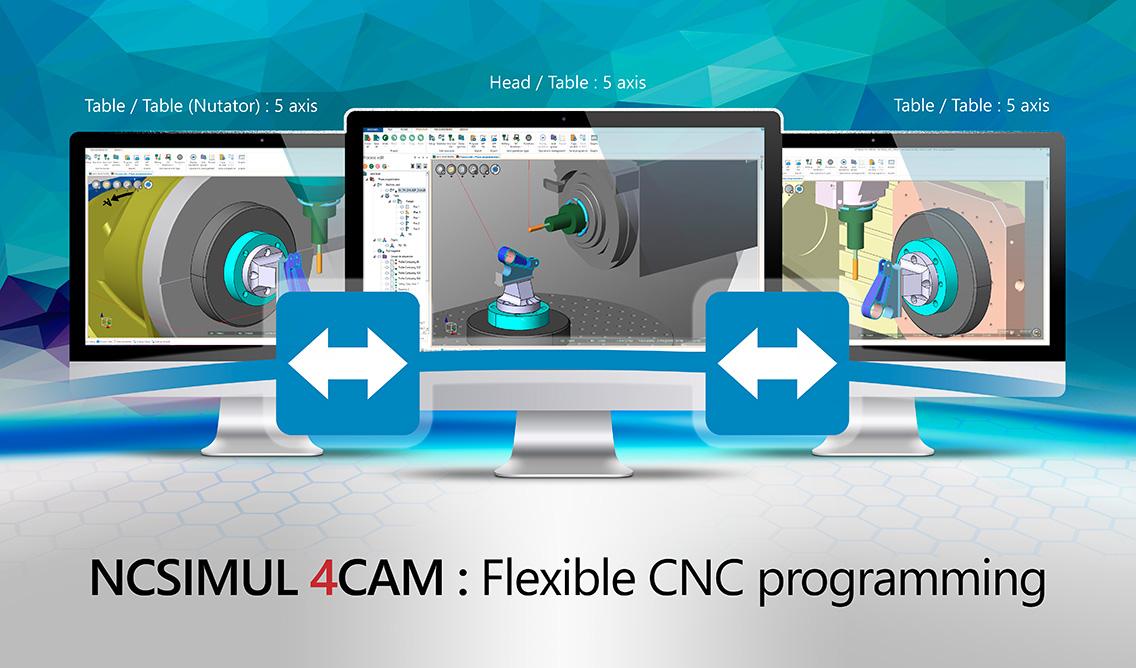

At the exhibition area at MIC2016, visitors can experience NCSIMUL SOLUTIONS at the SPRING Technologies' demo-point. In addition to its high-performance machine simulation, optimization and digital tool management, SPRING Technologies will be also presenting its latest development, the innovative NCSIMUL 4CAM, winner of the "MM Award" in the category Software at this year's metal processing trade fair AMB and awarded also a few months ago in France with the INNOVATION Award.

NCSIMUL 4CAM enables the automatic conversion of existing CNC programs with only a few clicks to new machines. Manufacturers won't lose time anymore with traditional and manual reprogramming operations, taking sometimes up to several days. This revolutionary approach opens the way to a flexible manufacturing, explains Herbert Schönle, General Manager DACH at SPRING Technologies: "Aerospace manufacturers face increasing cost and time pressure. NCSIMUL 4CAM generates ready-to-use and self-verified CNC programs for any machine and controllers. This enables manufacturers to switch fast and flexibly between their CNC machines and re-organize their production in seamless and integrated manufacturing processes." He proceeds: "As a result of our optimization capacity NCSIMUL users profit from significant time savings also already in the single CNC programs. With a detailed analysis and optimization of the cutting conditions and the removal of the material, on average a 20 % reduction of machining time can be achieved."

New production technologies for the aerospace industry in the spotlight at MIC 2016

The annually held MIC conference is organised by the Institute of Production Engineering and Machine Tools (IFW) Leibniz University of Hanover in cooperation with the Machining Innovations Network e.V. (MIN). The organisers expect more than 200 leading experts from aerospace technology to attend this year's event. The conference program consists of 4 sessions with expert lectures from industry and science about emerging trends, experiences and results in research. Among the presenting companies, there are for example, DMG Mori, Makino, PREMIUM Aerotec, Kennametal, Sandvik Coromant and SolidCAM.

A guided Tour in the IFW Laboratory, as well as an exhibition area and an evening gala are part of MIC2016. SPRING Technologies welcomes the attendees at its NCSIMUL demo-point at position A03 in the heart of the exhibition area.