INDUSTRIE 2014 : SPRING Technologies turns the spotlight on WYSIWYC®

The innovative, award-nominated solution will be demonstrated live on booth 5-T77, Hall 5A – with NCSIMUL Machine 9.1

SPRING Technologies, vendor of solutions that enable manufacturers to optimize the use of their NC machines, will be back this year at the Industrie 2014 show, from March 31 to April 4 at the Parc des Expositions de Paris Nord/Vlilepinte on the northern edge of Paris.

"Building tomorrow's solutions", is the theme of the 2014 edition of France's marquee INDUSTRIE show. Since 2013 SPRING Technologies has been anticipating and offering a whole suite of instrumented, intelligent, and interconnected — in a word, SMART — solutions, based on its NCEXPERIENCE® vision.

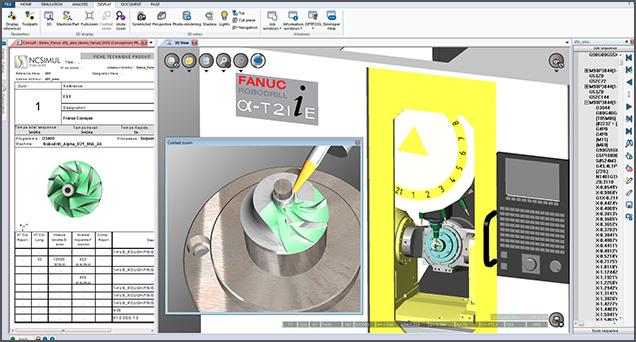

As from March 31 the full set of modules that make up the NCSIMUL SOLUTIONS range will be showcased on booth 5-T77, Hall 5A. The show is an opportunity to discover and test tool management with NCSIMUL TOOL 2.4, DNC and real-time machine status with NCSIMUL DNC 8.21, and NCSIMUL Machine 9.1, the latest version of SPRING's flagship software for machining simulation, complete with a range of new features including:

- Simulation of composite material lay-up;

- Full integration of the NCdoc document publishing module;

- Automated functions for an enhanced user experience.

Centerpiece of the show will be the new 100% mobile solution for the shop floor: WYSIWYC® (What You See Is What You Cut), nominated from among 35 products in the Technology category for the Trophées de l'Innovation awards at Industrie Paris 2014, a prize that acknowledges a product or solution that creates value from a new technology. The nomination proves that for SPRING tomorrow is already here today.

Synchronization, supervision, optimization, mobility, and real time

These are the watchwords embodied by SPRING Technologies in WYSIWYC®, a product that enables NC/shop floor managers to use a rugged mobile Toughpad FZ-G1 to manage several machine tools simultaneously, in real time and in sync in 3D, as they execute the NC program for real on the machine. This analytical capability is a valuable decision-making asset in the production environment.

In a word, WYSIWYC® is a professional solution for remote surveillance that makes daily machine operation secure in touch mode and in a virtual reality environment that offers unrivalled comfort and reliable machining, irrespective of the number of machines.

The new technology is a great step forward, optimizing productivity in the workshop, but Philippe Solignac, Corporate Marketing Director, SPRING Technologies explains that there is more: "We are witnessing a massive adoption of mobile tools that gives people on the shop floor more autonomy and an opportunity to rethink their working methods. It is a watershed in the technology. 3D machining simulation will be a big asset for adopters. Notably it will draw in young talent from the Y generation, a new wave of NC operators for whom mobility is at the core of the way they do their job. This solution is the perfect tool for training organizations offering different types of programming curriculum (5-axis, mill-turn, and special machine environments), eliminating the need for high up-front investment."

"If I had to single out three main benefits delivered by WYSIWYC®, I would say: 25% more productivity; an asset and a differentiating factor for hiring Y talents for the shop floor; an opportunity for anyone to learn NC programming in a VR environment."

We look forward to meeting you from March 31 to April 4 2014 on the SPRING booth, 5-T77 in Hall 5A, and offering you a live demonstration of the advantages delivered by the NCSIMUL SOLUTIONS, with a special focus this year on NCSIMUL Machine 9.1 and WYSIWYC®.