NCSIMUL at AMB2018: Meeting Point for Digital Pioneers

SPRING Technologies presents the Digital Cockpit for Intelligent CNC Machining

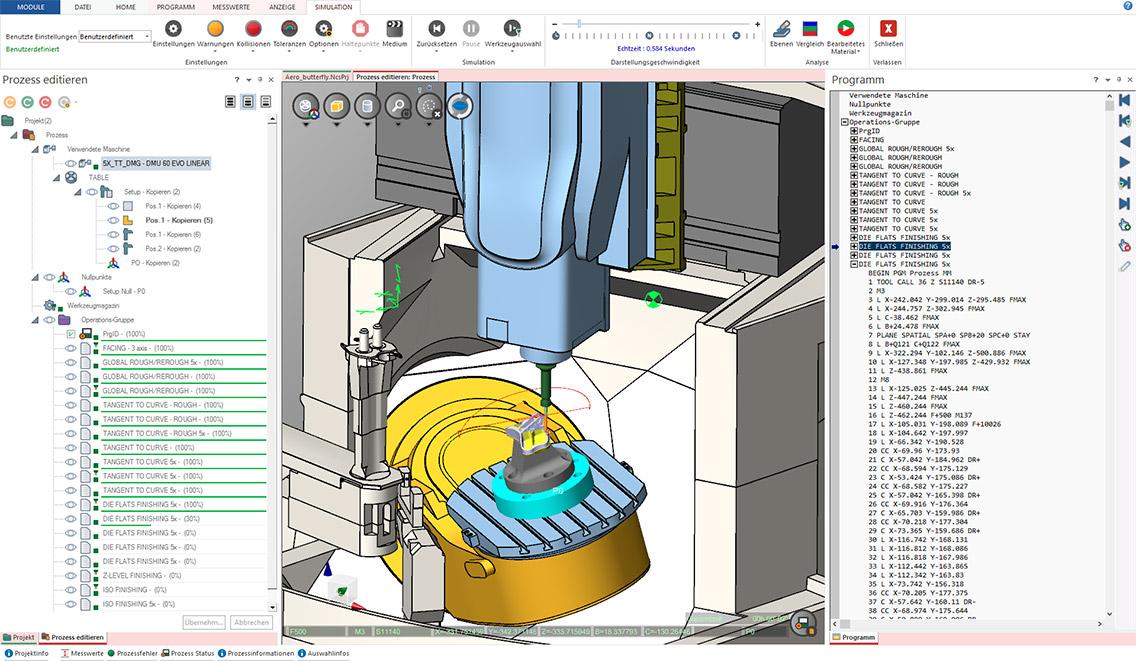

SPRING Technologies, a leading technology provider for software solutions to increase the efficiency of CNC machines, will again be present at AMB, the international metal-working exhibition in Stuttgart from 18 to 22 September this year. Visitors can directly experience the NCSIMUL Game Changing Technology during live demonstrations at the booth: Real-time overview of the entire shopfloor and machine switches with only a few clicks instead of time-consuming manual re-programming is the name of the game.

The company's latest release, available from summer 2018, will advance the manufacturer in the next steps. The focus is no longer on the performance of single machines but rather on the optimal utilization of the entire shopfloor - fully in accordance with Industry 4.0. To achieve this, a further module has been integrated into the latest version: NCSIMUL MONITOR. As a digital cockpit, it provides an overview about the use and availability of the different CNC machines, helping production managers to better manage their production capacity and to more flexibly respond to changes.

Flexibility 4.0 - the potential of a virtual shopfloor

Herbert Schönle, General Manager DACH of SPRING Technologies, describes a typical situation: “Production management receives the desired follow-up contract to manufacture a complex part. It's urgent, and in addition, the customer has requested some manufacturing changes. Problem: The 5-axis machine which has been used for this machining process is occupied for the next few days with a bigger program. Using NCSIMUL MONITOR, the production planner can now see the availability of all machines relevant for the production of this part. With NCSIMUL 4CAM, the original NC program can automatically be converted to the new target machine and control system. In addition, the program can, for example, be split to run on a 3-axis and a 5-axis machine, whereby the 3-axis machine executes the preparatory rough-machining processes and the 5-axis machine only needs to execute the simultaneous finishing programs. With NCSIMUL manual re-programming that usually takes days can be completed in only a few hours.” It is also an advantage when implementing new machines.

This is also true for manufacturing processes: The included NC simulation delivers error-free and collision free NC programs. “The days are over when a machine operator had to stand next to the potentiometer while the machine is run in,” says Schönle.

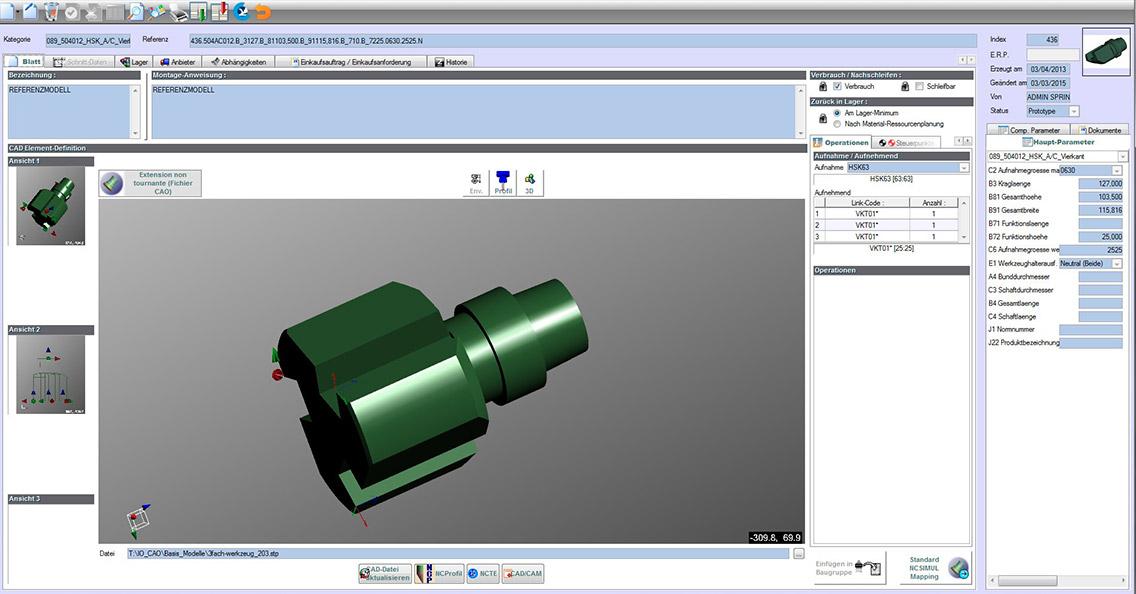

With NSCIMUL, all data about the machine tool, clamping systems, tools and further technology parameters are organized in a bidirectional data process. In the case described above, when changing machines the existing program will be directly adapted to the performance data of the new machine; suitable tools will be shown in 3D and, upon confirmation, directly fed into the program. By accessing machine tool data bases such as ToolsUnited, the necessary tools can be loaded into the system including manufacturer data and related graphics. To increase the acceleration of acceptance and provision of the complete machine tools, there are predefined master models available in the digital tool management NCSIMUL TOOL in accordance with DIN4003/ISO 13399.

Digital documentation to face future challenges

Modified NC programs and alternative manufacturing routes are also available for planning further follow-up contracts, since all modifications made in the NC program will be fed into the integrated digital document management system. As a result, shopfloor information is available in real-time and the current status can additionally be retrieved via mobile devices. This is a significant step towards paper-free manufacturing and, at the same time, provides a solution for many companies in the metalworking industry that are facing a hand-over to the next generation, as Herbert Schönle points out: “Digitalization helps to maintain and further develop knowledge which has been established in the company over decades.” Across company borders, all data can be shared with suppliers or customers. To protect this know-how, only encrypted final data is sent.

Focusing on digitalization and connected manufacturing, the manufacturer of innovative software solutions for intelligent CNC manufacturing sees himself fully in line with the concept AMB has chosen for this year. During the exhibition, the new special show “Digital Way”, which includes a congress and interactive showcases, will provide guidance for users how to practically implement Industry 4.0 and process digitalization. At the east entrance of the exhibition, vocational competitions in CNC turning and CNC milling of the German Championship of WorldSkills Germany will take place. SPRING Technologies is also a sponsor of the Worldskills Germany 2018.

Exhibitor-Logo:

SPRING Technologies, Eingang Ost EO120

Data:

What? Live demos, expert talks and presentation of industry-specific user cases; presentations during the AMB speaker's program. In the evening of the 19th September, SPRING Technologies invites “Pioneers of Intelligent CNC Manufacturing” to a small celebration at the stand.

When? 18-22 September 2018 from 9 a.m. to 6 p.m., Saturday until 4 p.m.

Where? Stuttgart Exhibition Centre, NCSIMUL Stand EO120 - directly in the foyer of the east entrance.

About AMB

At the AMB in Stuttgart from 18 to 22 September 2018 approximately 1,500 exhibitors will present their innovations and developments for metal-cutting and milling machine tools, precision tools, measurement technology and quality assurance, robotic, workpiece and machine tool engineering, industrial software & engineering, components, assemblies and accessories in a total area of more than 120,000 square metres. The organizers expect circa 90,000 international trade visitors this year. More details at www.messe-stuttgart.de/amb