Hexagon Helps Aerospace Manufacturers Prepare For Tomorrow, Today

Siane visitors to see reverse engineering, simulation and time savings from Hexagon’s digital chain

Because “tomorrow is being prepared today,” the Hexagon group will present software solutions at the Siane exhibition in Toulose, France, enabling aerospace manufacturers to take their businesses to the next level.

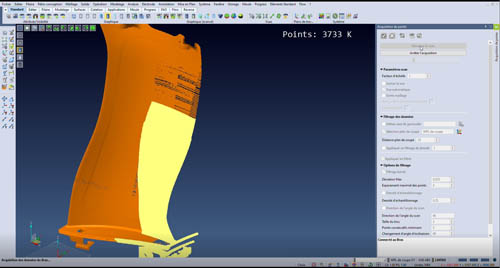

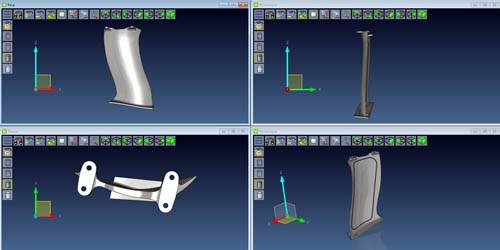

Visitors to stand B81 at the trade fair, from 20 to 22 October, will see how an aerospace part progresses from reverse engineering through to programming. And it’s even easier to prepare parts in VISI now, as recent updates to the software’s Reverse CAD module have improved the reverse engineering process. The digitisation operation has been enhanced with the display of the point cloud in shadow, allowing more accurate and faster feedback; and reverse operations now benefit from faster and more accurate surface creation.

On-stand demonstrations will also show significant time savings through improved cycle times for surfacing, contouring and Waveform, using the 2021 versions of Hexagon’s CAM software, EDGECAM, and simulation solution NCSIMUL.

EDGECAM

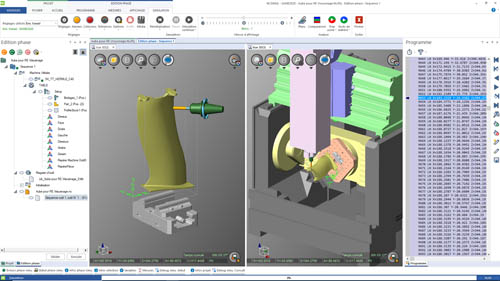

An increase in productivity gains has been achieved by reducing calculation times, thanks to EDGECAM 2021’s improved parallel processing capacity. And two of the most popular machining cycles - roughing and contouring - benefit from improvements to the algorithms of the software's multi-tasking technology.

Three significant time savings : EDGECAM's Waveform high-speed roughing strategy is now much faster for generating toolpaths for solid and wireframe components. Miguel Johann, Product and Sector Manager, says: "Numerous benchmark tests show a 30 per cent improvement in calculation times compared to the previous version." The use of the contouring cycle's undercut function has resulted in gains of between 40 and 60 per cent, depending on the size and complexity of the part.

NCSIMUL

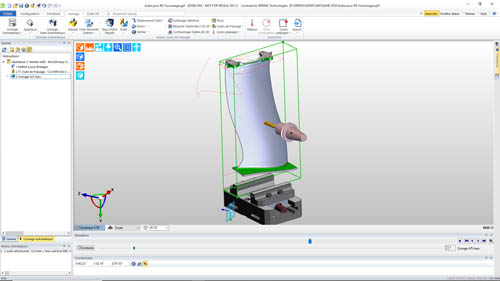

Hexagon’s solution for machining simulation and collision avoidance creates a digital twin of any NC machine. NCSIMUL Machine users can easily develop and validate their ISO programs remotely, offering more flexibility - compensating for the reduction of on-site personnel, which has proved to be particularly valuable since COVID-19 led to the introduction of widespread homeworking and social distancing.

NCSIMUL 4CAM allows users to manage and transfer programs from one machine to another in one click without re-programming CAM.

Samantha Mayet, Regional Marketing and Communications Specialist, concludes: “Because tomorrow is being prepared today, formalise, digitise, automate and monitor your business processes with Hexagon software solutions - the pillars of digitisation within a single offering.”

Meet the technical and sales teams of Hexagon Production Software - Siane Exhibition - 20 to 22 October 2020 - Stand B81