SPRING Technologies announces the new version of its cutting tools management solution : NCSIMUL TOOL 2.5

Integrating the ISO13399 standard, NCSIMUL TOOL 2.5 fits seamlessly into your global machining process from CAM through G-Code simulation to CNC Machine

SPRING Technologies, vendor of solutions that maximize the productivity of CNC machine tools, announces version 2.5 of NCSIMUL TOOL, its solution for the real-time management of cutting tool data and processes. With enriched user experience and performance, new integrated interfaces and support for the ISO13399 international standard, NCSIMUL TOOL 2.5 embodies the SPRING Technologies philosophy, increasing security and productivity and getting the full value of your cutting tools. A new step forward on the path to SMART Industry!

"Our solution, NCSIMUL TOOL, significantly shortens global machining cycle times", explains Olivier Bellaton, Managing Director of SPRING Technologies. "Once again we are using our expertise to bring our users rock-solid certainty that their cutting tools are production-ready. NCSIMUL TOOL 2.5 brings them solutions that are tailored to their needs."

NCSIMUL TOOL in a nut shell :

- Identifies the best available tool and optimal cutting conditions, taking into account machine, tool, and material characteristics and operator feedback

- Manages, plans and prepares tool inventory in real time

- Secures the best selection of physical tools via the library of existing tools

- Virtual tools libraries directly accessible from main CAM systems thanks to NCSIMUL TOOL/CAM interfaces

New features in NCSIMUL TOOL 2.5

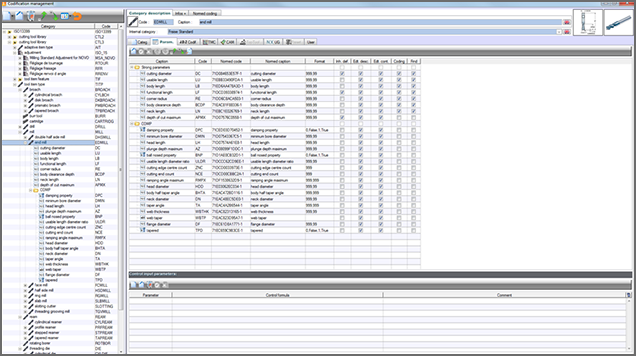

INTEGRATION of the ISO13399 standard in NCSIMUL TOOL :

By standardizing its tool data, SPRING Technologies addresses the needs of professionals who need ways to manage their cutting tools.

ISO 13399 international standard - associated with the STEP standard – describes the parameters and characteristics of all the tools by associating a universal code (for exchanging data between CAD, CAM, PDM etc.), thereby delivering invaluable time-savings and guaranteed higher quality.

Differences in the terminology and identifiers used by tool suppliers will soon be a thing of the past. Integrate the ISO 13399 international standard and go universal!

ENHANCED USER EXPERIENCE :

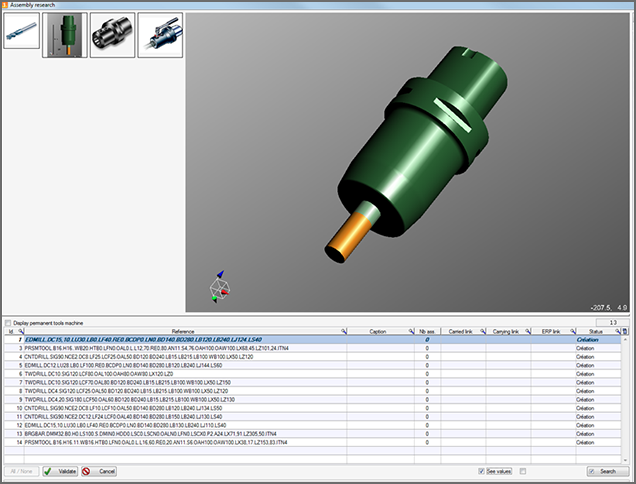

- A more powerful tool search function, with interactive parameter display for greater speed and ease of use. The new search module addresses the need for greater production efficiency, enabling a 30% time saving

- Upgraded "BLUM" laser module. This module can be used to measure tools on the bench when this cannot be done with the machine's own laser. Bore diameters declared in the ISO file are systematically sent to the BLUM module in order to automatically generate tool measurement programs that can be read by the Blum laser. Operators can therefore control whether or not the tool will be checked, thereby ensuring time-savings, and security about the reliability of the choice.

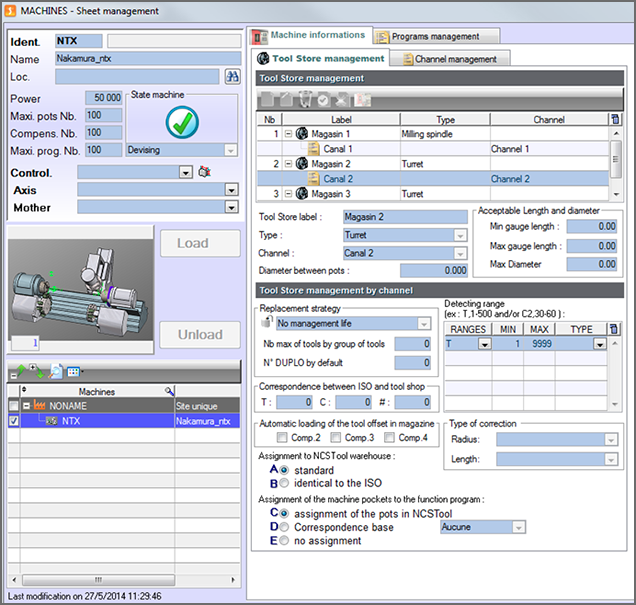

- Improved setup of tool size constraints, optimizing the use of tool magazines by analyzing and managing the footprints of the physical tools. The software now offers the simplest and most universal available scripts to ban tools that are too big to be stored in the magazine.

- User authentication by Active Directory makes it possible to manage all the users in the corporate network. This is because users, whoever and wherever they are, can now connect using their Windows access codes.

- Screen appearance has been made more consistent in the upgraded MMI and program windows are now more user-friendly.

- The multilingual database has been enriched to facilitate multi-site deployment of the same database across different countries, with the content being adapted to the user's local language, where families and search criteria were formerly offered in a single language (standard: FR, EN, DE, mandarin CH).

- Element traceability after code changes: changes in tool codes are automatically propagated under the management of user-definable Workflow (work status, change traceability, etc.).

ENHANCED PERFORMANCE :

- The integration of NCSIMUL Machine's NC decoding engine removes the limits in complexity of NC programs supported by NCSIMUL TOOL. The software can now import any program, however complex.

- The programming module can now be used to modify the CAD gauge of an assembly – notably in turning operations –, and the tracked point (Imaginary Tool Node) on the insert, by indicating the appropriate ITN N° in the lathe setting. Tool programming for multi-channel machines is now supported.

- Machine parameters are now declared by tool magazine and channel. The management of tool assignment and optimization strategies by magazine is accessible for multi-channel and/or multi-magazine machines.

ROBUST INTEGRATION via a range of new INTERFACES

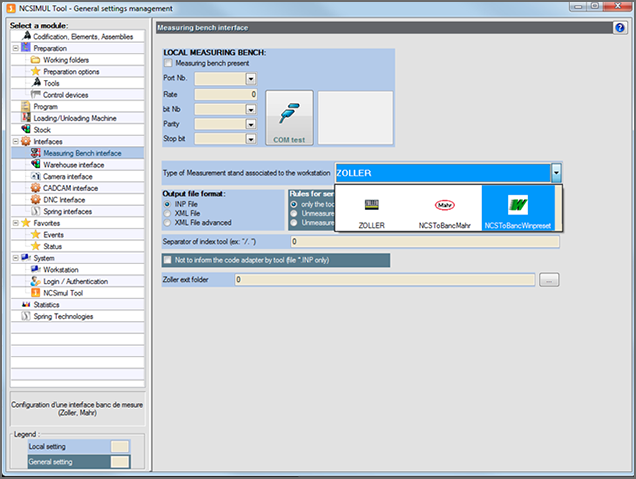

- New interface with WINPRESET: NCSIMUL TOOL is now connected with the WINPRESET bench to manage functions including measurement, file write and transfer, and magnetic labels.

- New interface with NX: supports tracking points in milling, drilling and turning. Tool bases can now be generated automatically in NX format (the virtual tool base is transformed into a NX library), and conversely NX native 3D tools, synchronization between the physical tool base in the workshop and the virtual tool library.

- Interface with the MATRIX storage cabinet: NCSIMUL TOOL inventory can be updated automatically from the files created by automated Matrix storage cabinets, enabling the synchronization and management of tool inventory in NCSIMUL TOOL

- New TOPCAM interface: the assembly search screen is positioned automatically at the workstation site: multi-site assembly management for internal and outsource users, who only access the tools defined for their own production site or the customer's tools.