SPRING Technologies wins major 2016 Innovation award with NCSIMUL 4CAM

A jury of Industry 4.0 experts singles out NCSIMUL 4CAM in the "Digital Tools" category

SPRING Technologies, vendor of software that optimizes the use of Numerical Control machines, is proud to announce that its NCSIMUL 4CAM module has won the Innovation Trophies award at France's INDUSTRIE 2016 trade show, in the category "Digital Tools". The award acknowledges a decisive technological breakthrough. "Programmers have been dreaming of this for 30 years; SPRING has done it," said CEO, Gilles Battier. "Of all the innovations SPRING has developed since we established the company in 1983, NCSIMUL 4CAM is the one I am most proud of. Customers have long been hoping to bridge the technological gap. The solution will enable them to step resolutely into the Workshop of the Future."

VIDEO : NCSIMUL 4CAM

WINNER Innovation Awards 2016 : Digital Tools

Mr. Battier continued, "If the Factory 4.0 paradigm is going to help industry anywhere in the world to make the decisions that will be vital for competitive capability, there is no alternative: Factory 4.0 must be flexible and agile. NCSIMUL 4CAM has been developed to streamline the digital process and rethink the approach to CNC programming. We bring a concrete answer to today's issues: a quick and easy way to manage the complexity of technology and production to optimize productivity."

What is NCSIMUL 4CAM?

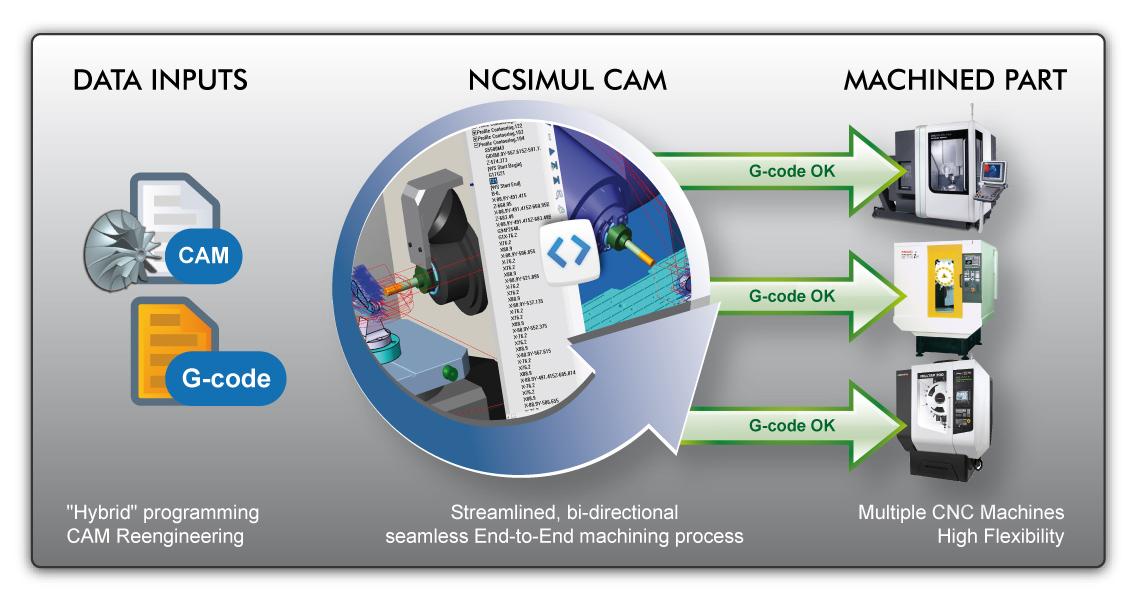

The innovation embodied in NCSIMUL 4CAM, a module of the NCSIMUL SOLUTIONS suite, has brought the finishing touch of flexibility to the CAM systems available on the market today. With NCSIMUL 4CAM, new NC machines can now be quickly integrated into the production cycle, and existing machines can be redeployed in the shop to optimize their uptime, while tool paths are reprogrammed in just a few clicks to speed up production rates across all types of NC machines.

The three major innovations in NCSIMUL 4CAM:

- Machine change in just a few clicks on even machines with differences in kinematics, controller, tools, and cutting conditions, to deliver a fully flexible production tool.

- Hybrid programming using heterogeneous input data from CAD/CAM systems (3D, tool paths in APT/CLdata format) or existing NC programs (ISO). Error-free program creation and, consequently, a significant reduction in lead times from prototype to mass-production, or in repurposing legacy programs to new machines.

- No more external post-processors, thereby reducing development costs, debugging cycles and related maintenance.

More Trophy award statements:

Gilles Battier, CEO of SPRING Technologies

"Thirty-three years ago SPRING, (an acronym for Société de Programmation et de Recherche en Informatique Numérique et Graphique), was founded, as its name suggests, to search for programming solutions in digital and graphic IT technologies with a view to delivering these solutions to the reality of machining on the shop floor. The prize rewards our vision of the Factory of the Future and the R&D work that we have undertaken with the Centers for Competitiveness: ASTECH, EMC2, SYSTEMATIC and VIAMECA. I'd also like to highlight our Open Innovation partnerships with major corporations: SAFRAN, AIRBUS and the FREYSSINET Aero Equipment (a small and medium company), with whom we have been working for over 5 years, helping us to develop NCSIMUL 4CAM and, thus, contribute to our award-winning success today. We offer our customers solutions that bring them the flexibility they need today and going forward and we support their efforts to step up production rates, reduce unit machining cycles, increase machine uptime and help to relocate manufacturing back to France, thanks to more competitiveness. These are the watchwords that drive our teams at SPRING to keep on innovating. Lastly, I must thank our financial partners BPI France, CM-CIC Innovation and ACE Management for supporting our development effort".

Philippe Solignac, Corporate Marketing Director, SPRING Technologies

"Most industrialized nations have introduced substantial programs to provide financial and political support to help their industries become the most competitive by 2020. In France these initiatives include: "Industry of the Future", while Germany has introduced "Manufacturing 4.0" and the USA has its "Manufacturing Renaissance". All share the same mantra: the need to make manufacturing processes agile and capable of reconfiguring themselves in order to adapt to the demand of fluctuating markets, while maintaining maximum levels of productivity. Today's manufacturers have to be capable of offering an increasingly customized approach and consequently make their production tools more flexible to completely match their needs. NCSIMUL 4CAM is the right answer for all manufacturers seeking to meet this 4.0 challenge, from major corporations to SME."