SPRING Technologies with an expert lecture at the mav Expert Forum "Minimizing Set-up Times"

The perfect combination of digital engineering and production

SPRING Technologies will participate with both an expert lecture and live demonstrations at the upcoming mav Expert Forum "Minimizing set-up times" on June 8th 2016 and present how intelligent and user-friendly NC processes can successfully reduce set-up times on the machine and improve productivity in CNC machining.

The Expert Forum is organised by the mav journal, published by Konradin, and focuses on the emerging challenges in production by an ever increasing diversity of variants and smaller batch sizes: the set-up time – the time required to re-set the machine for the next machining operation– thus becomes a key factor. Manufacturing companies with seamless and intelligent processes being able to change rapidly from one production step to another always maintaining a high level of productivity, achieve an important competitive advantage. Machine tools, programming, controllers and software, tools and mounting systems must all be brought to function in harmony.

The concentrated expertise of efficient production

With the companies Renishaw, Schunk, E. Zoller, Maschinenfabrik Reinhausen, Moldtech, MATSUURA, FANUC, Erdrich, Walter and SPRING Technologies – there are ten technology leaders from different areas in the field of the metal-removing production participating in the event and presenting their solutions for faster set-ups and higher productivity.

With an expert lecture on "Minimizing set-up times by combining digital engineering and production" SPRING Technologies will show in particular how the transition on a machine from one production program to the next can be made efficiently and without any friction. "This is exactly where the digital world meets the workshop", declares Kai Lehmann, Account Manager at SPRING Technologies.

When the set-up becomes collaborative and mobile

In the conventional manufacturing process, the machine operator would receive the information for the next set-up usually by a data sheet – on paper.

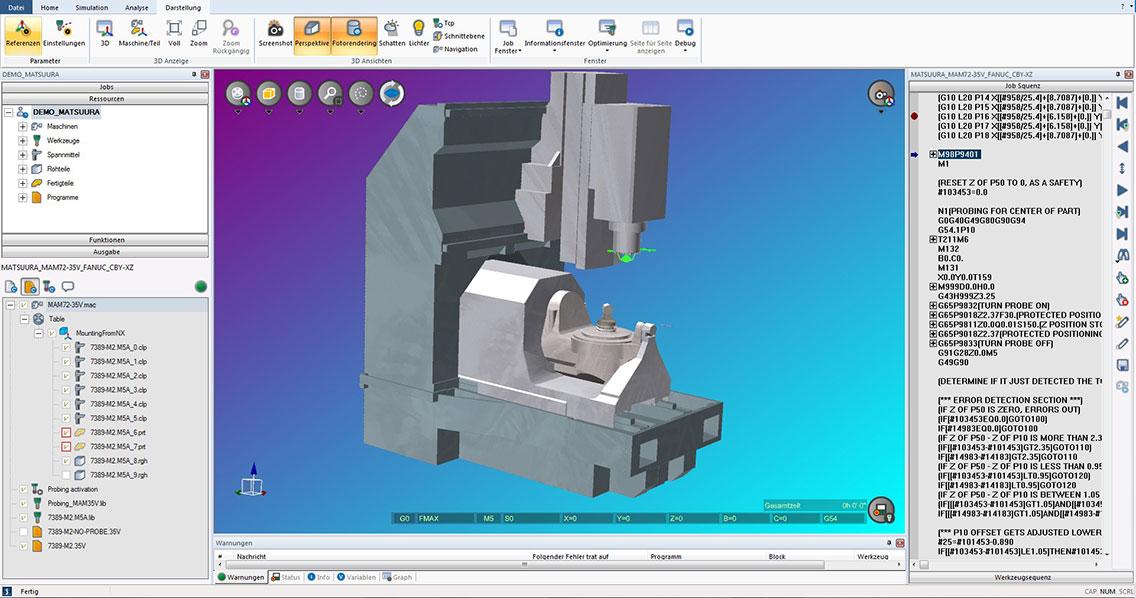

NCSIMUL SOLUTIONS simplifies and digitalizes this process: before implementation, the NC programme gets verified, checked for errors and simulated – ensuring 100% collisions safety on the machine. An optimization of the NC program can reduce dramatically the machining time by further 20%. Decisive for the set-up procedure itself: the simulated program can be generated automatically also as a 3D NC video. With NCSIMUL Player the machine operator can thus call up the simulation via an integrated player. In this way he has all relevant NC information available in an interactive 3D view, also when using mobile devices like, for example, a Panasonic Toughpad. Additional information such as tool descriptions, procedures, instructions can be called up directly from the related tool data bank.

"In this way work preparation becomes significantly faster and more convenient", Lehmann concludes.

With its solutions for intelligent CNC machining, SPRING Technologies goes even one step further. When companies want to switch from one machine to another – on the fly - or transfer existing NC programmes to new machines, with NCSIMUL SOLUTIONS it takes them just a few clicks to switch the machine, without any need of reprogramming. The newest release from NCSIMUL SOLUTIONS - NCSIMUL 4CAM - generates automatically new CNC machine programs from a formally created CNC toolpath and allows companies to switch between the different CNC machines, on-the-fly and without the need of reprogramming. This technological programming breakthrough provides manufacturers unparalleld flexibility on the shop floor.

Visitors of mav Expert Forum can experience the NCSIMUL SOLUTIONS software platform live during intervals at the Demopoint of SPRING Technologies.

The mav Expert Forum "Minimizing set-up times" takes place at the European headquarters of Maatsura Machinery GmbH at Wiesbaden (Germany).

In addition to the lecture programme and the activities in the showroom, the expert meeting will also provide opportunities for exchanging experiences and networking. The number of participants is limited to 100 visitors. Register online up to the 3rd of June 2016 at http://www.mav-online.de/ruestzeitminimierung. Registration is free of charge for guests of SPRING Technologies.

mav Expert Forum "Minimizing of set-up times"

WHERE?

Maatsura Machinery GmbH, Berta-Cramer-Ring 21, D-65205 Wiesbaden-Delkenheim, Germany

WHEN?

June 8th 2016, 09h00 – 17h00