The Digital Cockpit for intelligent CNC Manufacturing

NCSIMUL at ILA Berlin 2018

SPRING Technologies, software provider for enhancing the efficiency of CNC machines, is announcing its participation at ILA Berlin 2018. To what extent can productivity be increased and what are the competitive advantages when using NCSIMUL in the aerospace industry? These are some of the questions that SPRING Technologies aims to comprehensively answer at the ILA in Berlin from 25 to 29 of April. Because when it comes to parts and quality, the aerospace industry faces strict rules and requirements. With NCSIMUL, manufacturing mistakes can be avoided and higher quality is guaranteed. In effect this means: to optimize processes, save time and reduce costs.

Save time: from several days to only hours

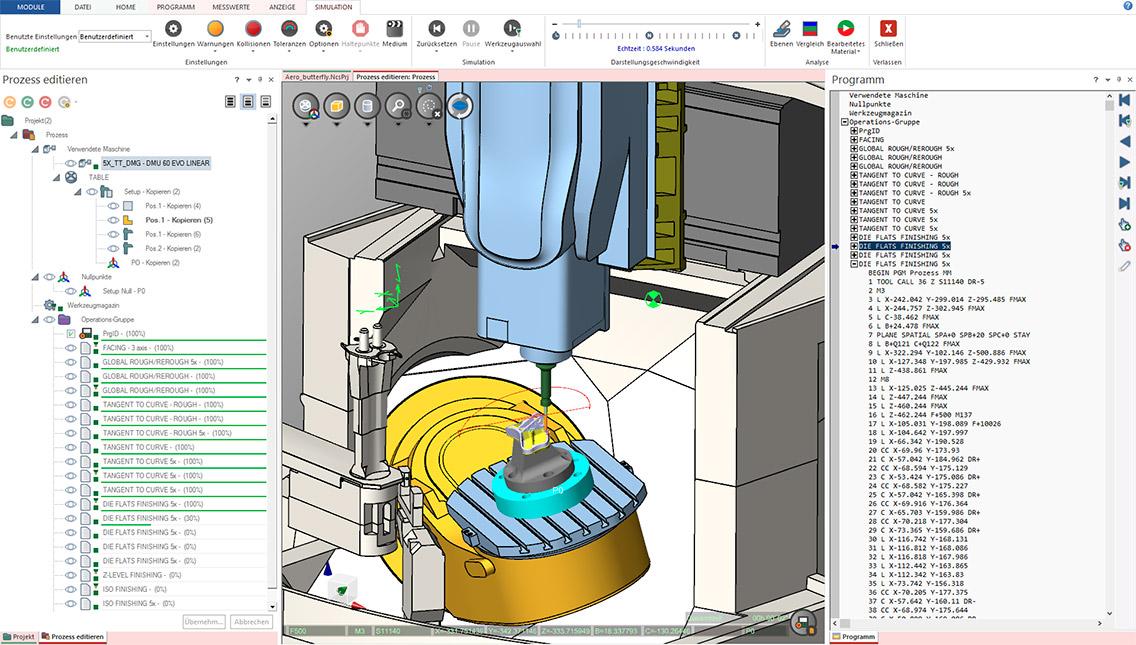

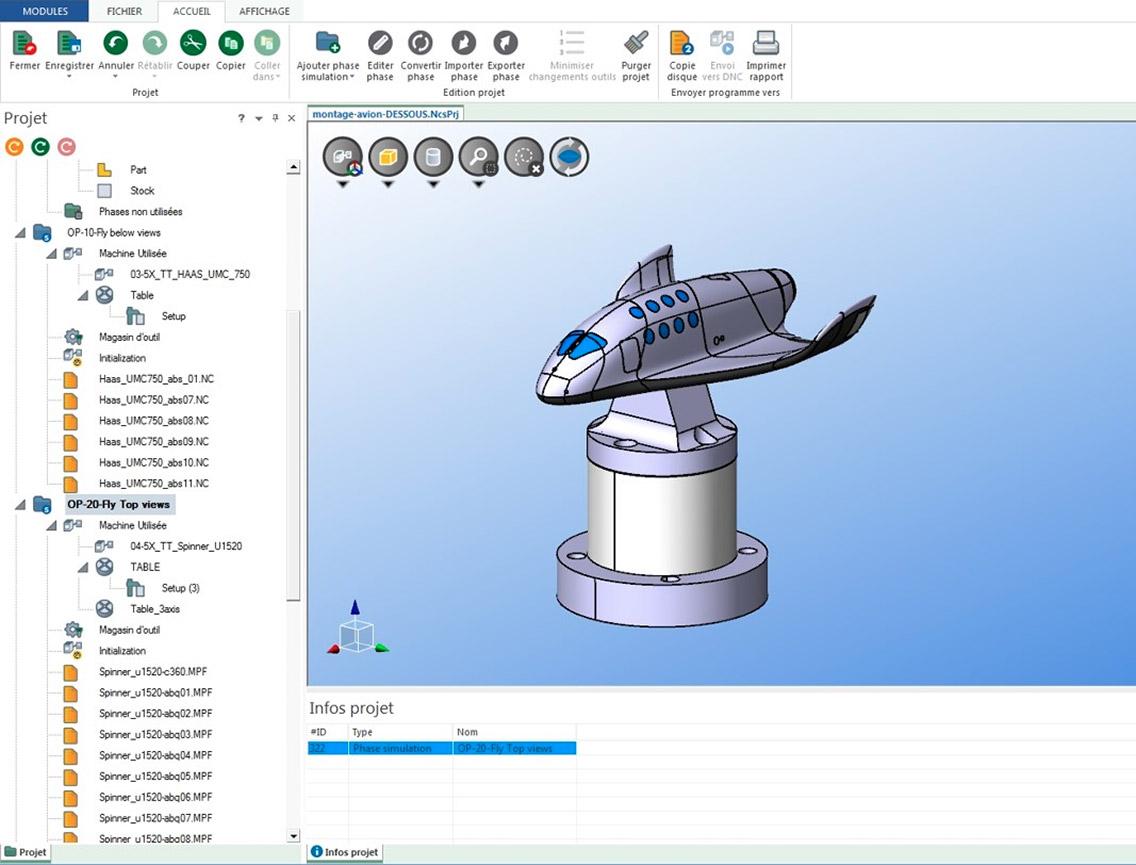

According to the manufacturer, the innovative and award-winning software solution NCSIMUL SOLUTIONS simplifies and accelerates the digital CNC process chain. By way of NCSIMUL 4CAM, users can automatically convert NC programmes to adapt to various machines, kinematics and controls with a few clicks. This avoids time-consuming manual reprogramming, which in some cases can take up to several days. It is even possible to split up a programme to use it on several machines, taking into account the dynamic rest material from other processes, a 5-axis process can, for example, be split up to be executed on a 3-axis and a 5-axis machine.

This results in a more flexible production workflow management and allows for better pre-planning. Particularly, suppliers are often subject to considerable pressure when trying to meet expected delivery dates. Here, no one can afford to make mistakes. For this reason, NCSIMUL checks the NC code of all programmes for possible collisions and, in a next step, optimizes the programme regarding air cuts and feed rate. The results are error-free NC programs and an anti-collision machining, but also a considerable reduction of set-up times and faster machining. NCSIMUL is based on an end-to-end bi-directional data platform, transferring technology data to machines, processing, a tool management system and digital documentation. In practice, this means that the user has all data interactively available and can adapt them to the performance specifications of the machine with a click. Digital tool management is enabled by way of the integrated 3D module.

Flexible and interactive processes

The opportunities which this approach may bring to the modern working world will be discussed by SPRING Technologies at their presentation “Flexible and interactive Work Processes in digital CNC Manufacturing” on Thursday, 26 of April during the “Work 4.0” conference organised by the Supply Chain Excellence Initiative.

To what extent NCSIMUL allows for time reductions and productivity increases shall be highlighted in a case study focusing on the French aerospace supplier Le Piston Français. France is this year's partner country of the trade fair. Being partner of GIFAS, the trade association of the French aerospace industry, SPRING Technologies will be present in the French GIFAS pavilion (hall 6, stand 392) and be part of the International Supply Centre. The GIFAS messages “know-how” and “innovation” are also core values with SPRING Technologies. In association with GIFAS, the technology company is strongly engaged in France.

About the ILA Berlin

At the ILA Berlin, the aerospace industry presents its innovations in the five topic areas of Aviation, Space, Defence & Security, Supplier and Special Features. More than 1,000 trade exhibitors will be present - ranging from civil aviation to defence and security to aerospace, from large concerns to highly specialised suppliers. Special match-making and speed-dating events for the supplier industry will ensure an attractive ILA schedule. At the ILA Career Centre, exhibitors will have the opportunity to actively recruit young talents and to generate enthusiasm with students and graduates for one's own company. Nowhere else is there a greater focus on professional exchange than at the ILA.