The Hofmann Group achieves cost-effective production with Machine Simulation Software, NCSIMUL Machine

"We are well equipped for the future", says Markus Graef, Project Manager for automation and standardization

SPRING Technologies, vendor of solutions that enable manufacturers to optimize the use of their NC machines, explains why the Hofmann group chose NCSIMUL Machine.

Corporate presentation

The Hofmann Innovation Group, headquartered in Lichtenfels, Germany, stands for full service engineering and offers everything in its product portfolio from the development of a product through rapid prototyping and rapid tooling to series tools and the production as well as the assembly of small series.

With about 480 employees and over 50 years of experience, the company is one of the most well-renowned service-providers for the plastics-processing industry worldwide and across multiple sectors.

Smoothly-run production processes, precision manufacturing and high-quality, high-grade products are the basis of its success as an enterprise. For many years, Hofmann has been placing great emphasis on the standardization and automation of manufacturing.

Main Challenges and Key Output

Collisions while machining can be costly: it brings about high maintenance costs, machine down-times and delays in delivery. In businesses where complex NC (Numerical Control) machines are used, the minimization of the risks of collisions and tool failures are therefore an absolute priority. Those responsible are at the same time careful to minimize the necessary test times (prove-outs) for the NC programs and to optimize cutting conditions.

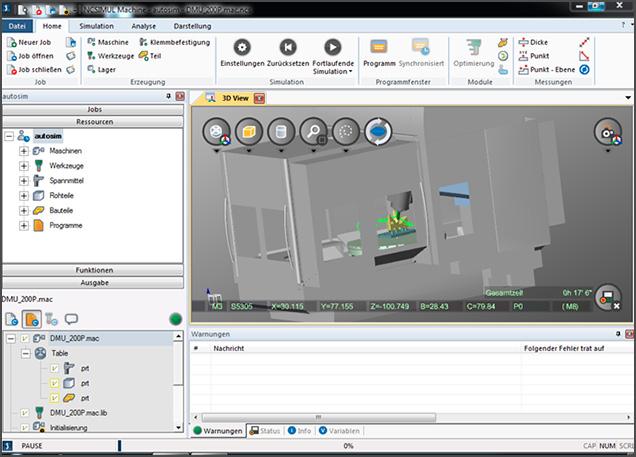

In this regard, to achieve the optimum and increase total productivity, the Hofmann Innovation Group has opted for the implementation of the CNC simulation software, NCSIMUL Machine.

Thanks to the use of the NCdoc add-in, enabling the automated generation of technical data sheets, CNC operators can directly access to their digital and interactive machining instructions as well as related CNC machining simulations for a perfectly streamlined and secured machining process.

Save time with a fully automated machining process

All computer-controlled processes can be tested and checked for errors with the help of CNC simulation tools before real operations get started. Thus damage to machines and additional costs (tool breakage for instance) can be prevented - most of all if the simulation process becomes fully automated.

To be able to carry out exact and extensive simulations, the leaders of the Hofmann Group decided in 2008 on the introduction of NCSIMUL Machine and NCdoc add-in by SPRING Technologies with a suitable automation interface: "We had a competitor's product in use before, but wanted to convert to fully automated processes. SPRING Technologies was the only CNC software vendor whose solutions met our requirements", reports Markus Graef, Project Manager for automation and standardization with Hofmann.

The software ensures that testing times are reduced on the machine so that the productivity rates are increased and development times are shortened. At the same time, the risk of tool breakage is noticeably decreased. The solution runs completely self-sufficiently on the server, without the need for the programmer to oversee the simulation in front of the screen. In addition, NCdoc delivers, in a file via email including text and videos, a complete representation of the machining simulation process and related work instructions so that CNC operators can read and secure their tasks.

Easy and quick implementation

The main focus with the introduction of the solution was above all the customization of the interface, which was finally completed after a six-month trial. For the approximately 20 users in the company itself, the transition phase also ran smoothly: after a one-day training course, the handling of the workflow was already second nature for all employees. Today, users benefit from the elaborate features and the automation of routine tasks.

Markus Graef says: "The introduction of the solution went without a hitch and our individual wishes were entirely realized. Also today optimization processes are discussed together."

Ready for the future

The result is convincing: the full automation of Hofmann machining process provides for the fact that programmers no longer need to supervise the simulation process and can instead concentrate upon the feedback or the results of the automatically provided report's simulation.

Through the realistic simulation of the manufacturing process, the consequences of state changes and processes are visualized.

Because no cost-intensive raw materials and operating supplies are used, the investment risk minimizes itself. The resulting free time available and financial resources can be invested elsewhere - in product development, for example.

Additionally, the risk of tool breakage has been reduced to zero since introduction of the solution. The solution delivers what it promises, namely a significant increase in the cost effectiveness of the NC environment - and more: "Now the machining process can be programmed more clearly, more safely and more time-efficiently - a big relief. Due to the possibility of continuous development, we are well equipped for the future", says Markus Graef.