NCSIMUL TOOL 2.2 takes the uncertainty out of planning your tool needs

SPRING Technologies, a leading player on the PLM and NCSIMUL SOLUTIONS™ markets, announces the release of NCSIMUL TOOL 2.2, the brand new version of its solution for the management of cutting tools. The French-based company is alone in delivering a comprehensive NCSIMUL SOLUTIONS™ suite, also including NCSIMUL Machine and TOOL SIMUL, and continuously enriches these solutions to address market needs.

Olivier BELLATON, Managing Director of SPRING Technologies explains : « Release 2.2 brings in a lot of new capabilities. We have in fact included over 100 new features and enhancements to help users to optimize their tool management. The main development is in production planning (MRP). What we deliver is the ability to plan basic tool needs (milling cutters, inserts, etc.) based on schedules, the start and end dates of production runs, tool lifetimes and tool types (consumable/regrindable). NCSIMUL TOOL users will now be one step ahead of their tool needs, cutting out the risk of stock-outs on the shop floor, and optimizing replenishment processes simply and automatically. With the new version we have also enabled a seamless integration of NCSIMUL TOOL in our customers’ digital processes (CAD/CAM interfaces, connection with physical resources). »

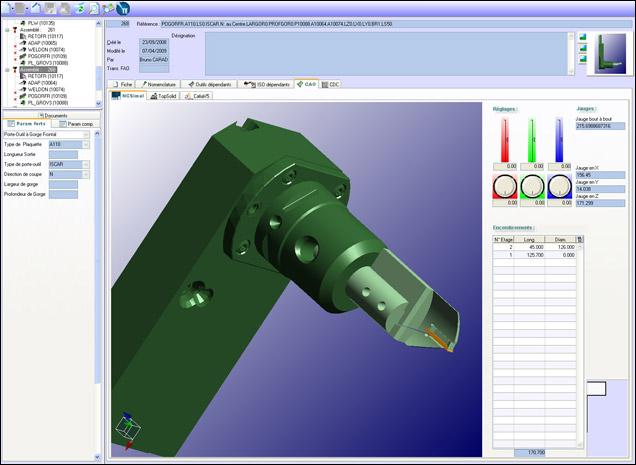

* 3D tool representation imported from CATIA

The top ten new features of NCSIMUL TOOL 2.2 are :

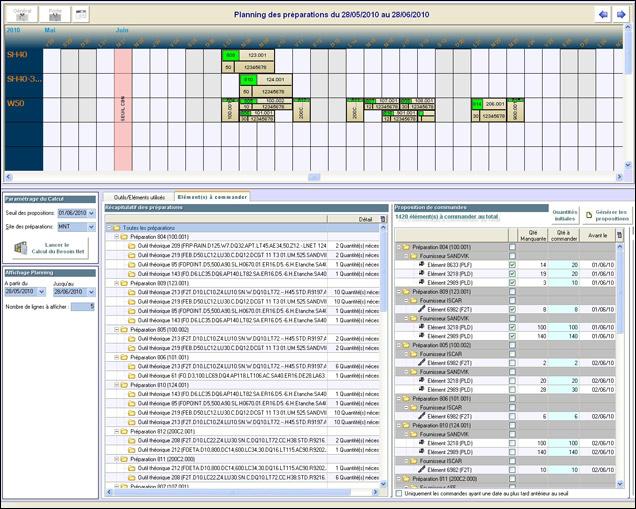

- Tool procurement based on the production plan (MRP),

- CATIA interface (tool generation in native format),

- SIEMENS NX interface (tool generation in native format),

- TOPCAM interface (supports turning tools),

- TOOLSIMUL interface (computes optimal cutting conditions for an assembly),

- ZOLLER XM interface (complete transfer of tool parameters to the ZOLLER bench),

- Management of inspection and tooling resources,

- Management of tool lifetime in the workshop,

- Enhanced tool coding module,

- Upgraded assembly creation.

Details of the NCSIMUL TOOL 2.2 enhancements :

- Tool procurement based on the production plan (MRP) : When the production schedule has been loaded, NCSIMUL TOOL computes the tool requirements and makes order proposals. The new module is based on sophisticated rules for defining consumable and regrindable tools, and also factors in the strategies for mounting the tools on the machines, and the lead times for procurement and regrinding. The module can be used to limit ordering to the requirements of the production plan, thereby optimizing procurement and inventory.

- CATIA Interface : NCSIMUL TOOL automatically generates CATIA Catparts of the assemblies from the element BOM. The basic tooling (milling cutters, drills, extensions, or attachments) does not have to be represented in CATIA. A parameterized shape, a simple profile or a representation in STEP or IGES format will suffice.

- NX Interface : NCSIMUL TOOL now directly generates tools in NX format, enabling machining operations to be simulated on the most accurate CAD representations of the assemblies.

- TOPCAM Interface : The TOPCAM interface has been improved for turning tools, providing better support for insert characteristics during material removal operations.

- TOOL SIMUL Interface : NCSIMUL TOOL now integrates the latest TOOLSIMUL V4 algorithms to determine the cutting parameters on the assembly.

- ZOLLER XML Interface : All the measurement parameters can be declared in NCSIMUL TOOL and transferred to the benches controlled by PILOT 3: this includes the measurement programs, cutter shape, lens type, etc... These parameters no longer have to be preset on the bench each time a tool is measured.

- Enhanced management of inspection resources and tooling. By integrating this capability into the preparation module, NCSIMUL TOOL enables an optimized management of the use of these resources from the workstation. This module identifies the location of all these resources in the workshop, keeps track of rate of usage, and schedules the calibration and renewal operations.

- Management of tool lifetime in the workshop : This functionality enables tool usage in the workshop to be optimized by managing lifetime in relation to factors such as the machined material types and geometry. Coupled with the new production planning capability, NCSIMUL TOOL calculates preparation needs based on the tools available on the machines, and the lifetimes of tools in the rack, and thus optimizes the tool mounting and measurement operations. NCSIMUL TOOL factors in machine strategies for managing similar tools and consumables.

- Enhanced coding module. The restrictions on the coding module that made it impossible to modify families when there was existing data have been removed.

- Upgraded assembly creation function. Assemblies no longer have to be ended with an attachment. This makes it possible to end them with an extension or to restrict them to a monobloc mill cutter.

* MRP screen

NCSIMUL TOOL 2.2 is available now.