SPRING Technologies announces the worldwide release of NCSIMUL 4CAM

NCSIMUL 4CAM, a new module for the NCSIMUL SOLUTIONS 10 platform, is now available on demand via the ncsimul.com website

SPRING Technologies, vendor of software that optimizes the use of NC machines, announces the worldwide release of NCSIMUL 4CAM, the module that puts the finishing touch to existing CAM programs.

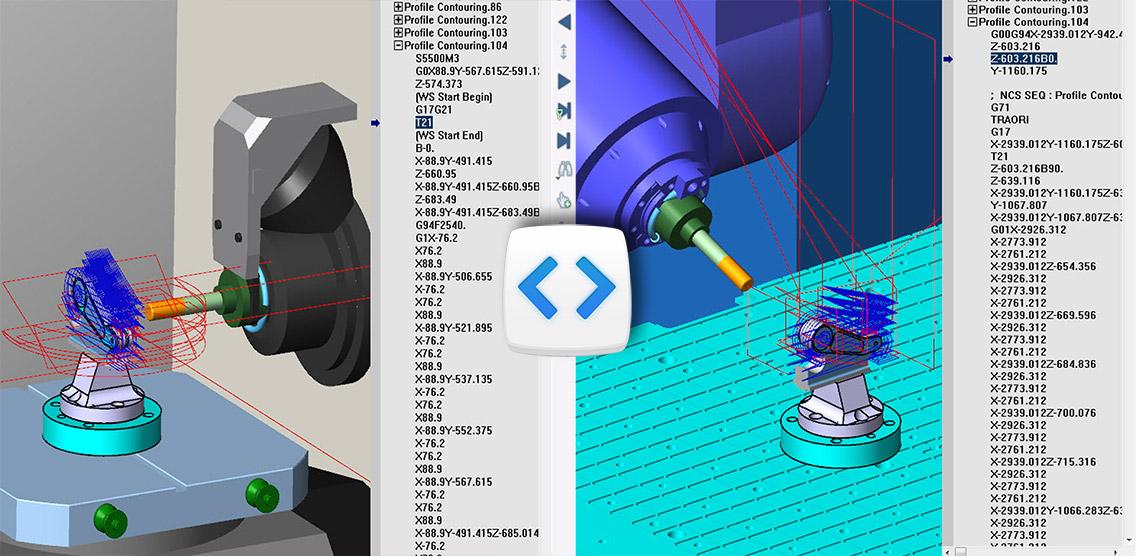

Based on CAM data inputs (CATIA®, NX®, CREO®, MASTERCAM®, and TOPSOLIDCAM®), or existing NC programs (G-code format), NCSIMUL 4CAM directly generates verified and optimized CNC programs without an external post-processor.

Ease of use and reliability were the watchwords in the development of NCSIMUL 4CAM, designed to streamline digital processes across a wide range of industries including Aerospace, Automotive/Transportation, Energy, and Medical instrumentation, where productivity and competitiveness are at a premium.

With the unique new solution, businesses in these sectors have maximum flexibility when selecting machines for their workshops.

Six highlights of NCSIMUL 4CAM:

- No more external post-processors, for a simplified NC process;

- 1-click reprogramming, for complete flexibility;

- "Hybrid" programming, for easy reuse of existing NC Data (g-code or CL-data inputs);

- Programming in native NC code verified and optimized for an all-in-one solution;

- Unique data file, to enable production to be transferred more smoothly from site to site; and

- Dynamic management of intermediary rough stocks for unrivalled ease of programming.

NCSIMUL SOLUTIONS 10: a simple and unified platform

NCSIMUL 4CAM is available as a module fully integrated into the new unified NCSIMUL SOLUTIONS 10 product platform. The other modules are NCSIMUL Machine (machining simulation), NCSIMUL TOOL (cutting tool management), and NCSIMUL MONITOR (machine status monitoring...).

NCSIMUL SOLUTIONS 10 will be marketed on either an "à la carte" basis or in bundled package:

- STARTER pack: to consult machining projects, the cutting tool base and to view CAD files.

- VERIFIER pack: to verify and optimize an existing G-code program generated by third-party software.

- PROGRAMMER pack: for users wishing to create a verified and optimized G-code program from any CAM file.

- ENGINEER pack: to create a new verified and optimized G-code program from any CAM file or from an existing G-code program.

- ACADEMY pack: the equivalent of the ENGINEER pack tailored to the Education and Research Center environment in the form of multiple licenses to deploy across classrooms.

More information is available about NCSIMUL 4CAM, via the new www.ncsimul.com website and at the upcoming shows where SPRING Technologies will be showcasing its products between now and the end of the year: South-Tec (USA), SIANE (Toulouse, France) MECT (Japan) and AIRTEC (Germany).

Olivier BELLATON, Managing Director, explains: "NCSIMUL SOLUTIONS 10 and its new built-in module, NCSIMUL 4CAM, marks the start of a new era, offering users in process planning departments an opportunity to break with 30 years of an iterative, heterogeneous NC process, by trimming down the number of stages and interfaces. The link between our customer' CAM deployment and actually having a machine-ready NC program or last-minute mounting will never have been so easy and so flexible."

What is NCSIMUL 4CAM?

NCSIMUL 4CAM directly generates native NC programs that are verified and optimized, taking into account the physical resources available in the Workshop (tools, cutting conditions, kinematics, NC machine controller, etc.).

The solution makes CAM data (APT neutral file / CL-data) or existing NC programs easy to use, generating an error-free NC program in just a few clicks for another machine, with different kinematics and controller. Manufacturers can thus quickly adapt their existing programs to new resources when retrofitting a machine, buying a new machine or repurposing the machining process. In the conventional digital process (CAM-Post-Processor-Machining Simulation), this task took several hours and even days. With NCSIMUL 4CAM it can be completed in a matter of minutes.

Likewise, if the target machine originally intended in the CAM program is no longer available because of a failure or for maintenance reasons, or because it is already being used to address a ramp-up in production, NCSIMUL 4CAM can be used in one click to reprogram the machining operation for another machine and automatically reconfigure the tool magazine. This makes production a fully flexible and agile process.