SPRING Technologies at the International Aerospace Supply fair: NCSIMUL SOLUTIONS 10 unveiled

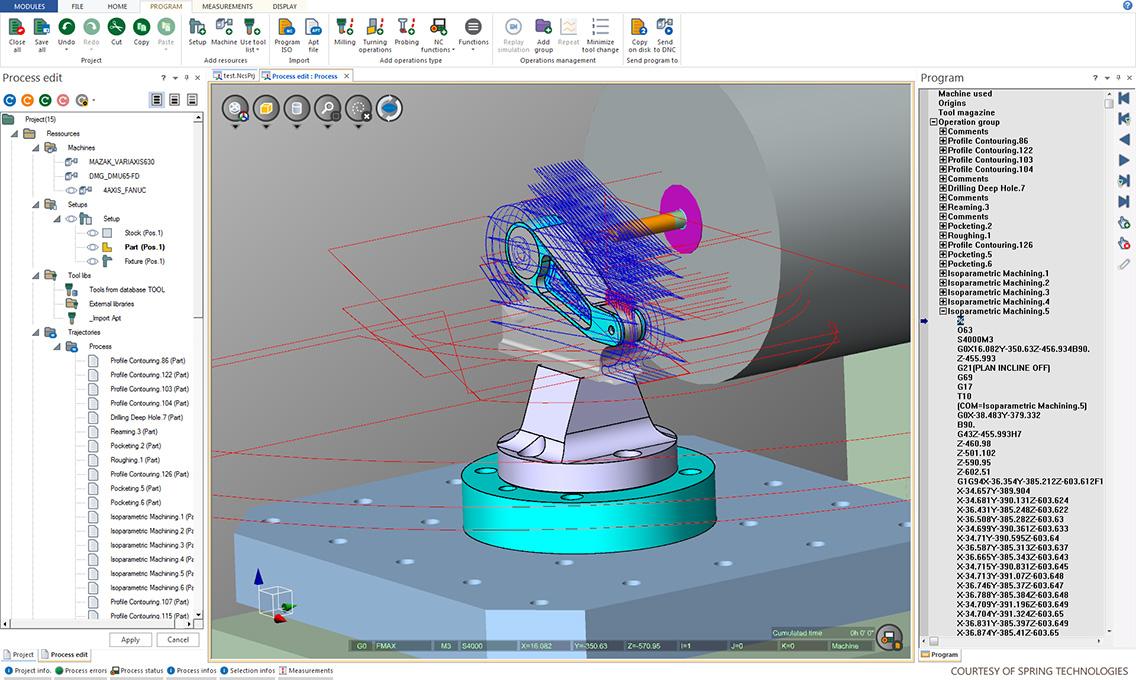

Rethink your manufacturing process with SPRING's unique all-in-one solution, streamlining the digital process of CNC machine programming

SPRING Technologies, vendor of software that optimizes the use of NC Machines, will present its unique NCSIMUL SOLUTIONS 10 platform at the AIRTEC tradeshow in Munich from November 3rd to 5th, 2015.

At booth C63 in Hall C3 visitors will discover the brand new module NCSIMUL 4CAM that directly generates verified and optimized CNC programs, while factoring in the physical resources available on the shop floor, including tools, cutting conditions, kinematics and machine controllers. They will also experience the technologically leading CNC simulation software NCSIMUL Machine, including the add-ons NCSIMUL Composites for the specific requirements of composite materials and OPTITOOL for the optimization of tool lengths and air cutting.

NCSIMUL SOLUTIONS 10 is more than just a new version: a technological milestone for manufacturing and production in the aircraft industry– unique and simple to operate. It facilitates a comprehensive, integrated control of the complete machining process, including:

- G-Code processing,

- G-code file simulation,

- Cutting and tool management,

- DNC G-code file management,

- Real time machine status monitoring

- Technical content publication.

This unique approach, streamlining the complete end-to-end machining process, delivers the tools and flexibility required to create the Factory of the Future.

Machine to machine reprogramming in 1 click

NCSIMUL 4CAM, the cutting-edge module delivers agile CNC programming in order to streamline the current CAM process, providing immediate collision-free programming and unparalleled flexibility on the shop floor. It takes just one click to switch between different machines and generate a valid new CNC program for another machine, whatever its complexity, kinematics and type of controller. In this way, production managers can adapt their manufacturing process easily to current requirements and resources.

"The aircraft and aerospace industry is confronted on a daily basis by the challenge of improving its production and under constant pressure to optimize costs", explains Gilles Battier, CEO of SPRING Technologies. "A multitude of companies in this field have been collaborating with us and adopted our solutions in order to control costs and production times. In this way, they can increase CNC machine uptime, thus improving their competitive position."

Collision-free from the first second

SPRING will also showcase NCSIMUL Machine, the realistic, intelligent and powerful CNC simulation software, together with the module NCSIMUL Composites for a smart 3D material lay-up simulation focused on composite materials. The focus will be also on the OPTITOOL module, for optimizing tool lengths and air cutting. With the correct start-up and run-down motions you can effectively avoid time-consuming and costly air cutting and in this way optimize your cutting conditions and high-speed feed rates.

The SPRING Technologies teams is looking forward to welcome you at hall C3 / booth C63.